As some of you know, my husband and I have a small business printing custom t-shirts for local groups and businesses called Phantom Chicken. What you might not know is that we have been trying to mix this and quilting into one piece of work. We are getting close to a finish!

I made a quilt top last summer and I had planned an elaborate print for it. Because my first plan was so daunting, it just never came to fruition… so we altered the idea a bit. Instead of one big image that would need to be broken down into many interlocking parts, we made a couple images to print randomly over the top.

Finished quilt top from Summer 2014

Since screen printing is a bit elusive to some, I thought I would share our process for printing here. In time I would love to set up a workshop so people could try this hands-on… maybe someday!

Screen printing has been done for thousands of years, and even though technology is pushing things to the digital world, you can still screen print. Old-school – by hand, which hasn’t changed much since it’s inception.

For this project, we used a special ink called Plasticharge. It’s a two-part system that is heat activated and instead of laying ink over the fabric, it actually releases the dye of the fabric. It leaves the feel of the print as soft as the rest of the unprinted fabric. The ink comes in 2 parts that need to be mixed about 45 minutes before printing. Mixing needs to be precise.

Mixing dishcarge inks for small project:

We used an old cream cheese container to mix in since we did not need much for this project. Besides the ink, we also need screens! To get a screen made, we first start with a design from the computer and send it to a camera-house that creates “film positives” for us. It’s just like a negative, only the parts you want to see (or print) are black and the rest stays clear.

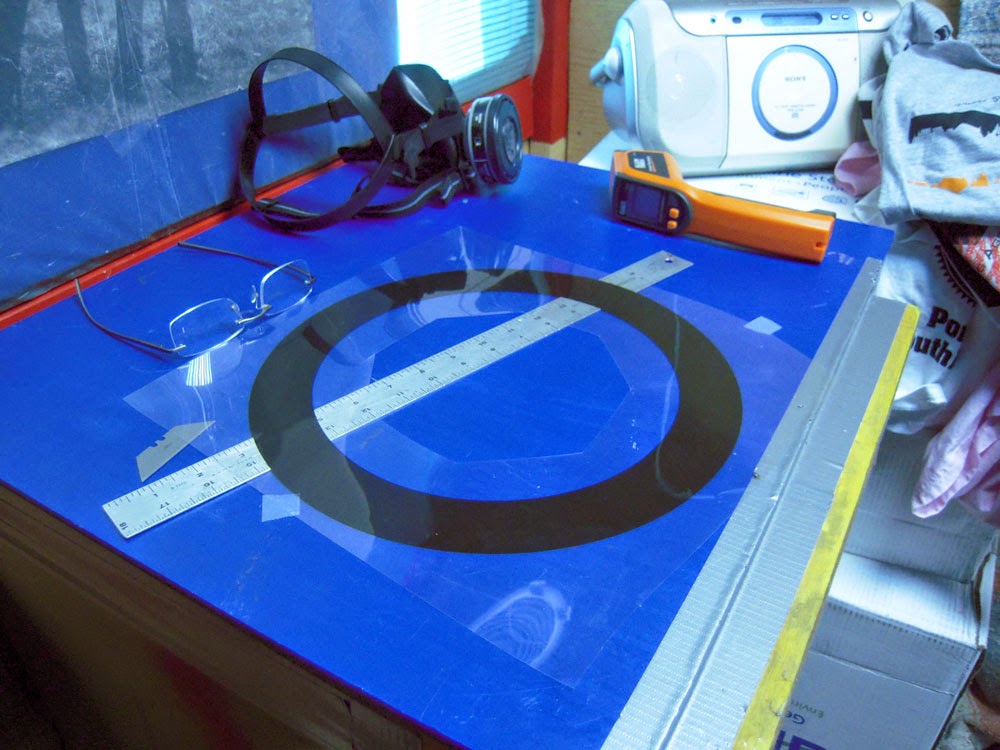

Above is the film for a large ring – what we want to print is black and opaque, and the rest is clear. We put this film on a screen covered in photosensitive emulsion and shine a light on it (shoot it) for about 15 minutes. The light hardens everything except what is under the opaque part. Water is then used to wash out the soft emulsion leaving a “hole” in the screen. Here are two screens, shot and ready for set up:

Once the screens are made, they can be set up on press. Luckily for this project, registration was not needed since everything is one-color and printing randomly. Otherwise registration can be the longest part of setting up. Here is one of these screens set up on press:

This was a fun project for Gregg, as I told him to print as desired – he had a lot of decisions to make.

Once he figured out where to put the next print, he put the quilt top on the press.

… And voila! A print on quilt! After this, the print needs time under a heating unit to “set” the ink into the fabric.

Now this one part of the print is complete – but Gregg had many circles and dots to use and each print was done individually. This took two afternoons to finish.

This top will need to be washed before quilting. The ink leaves a bit of a residue until washed, so today I am stitching around the sides to prevent fraying in the wash. I’m hoping to have this one finished for the next PMQG meeting. Time to think about ‘how to quilt this’… YAY!

What a great concept; I look forward to seeing the quilting too. What pattern/block did you use?

Thanks Nicole, I used "Anita's Arrowheads" by Anita Grossman Solomon. It was a very fast quilt top to assemble!